A research group led by Prof. WANG Pengfei from Xi'an Institute of Optics and Precision Mechanics (XIOPM) of Chinese Academy of Sciences denoted a technique to create regulable crack patterns using organics colloidal dispersion, which was applied to electromagnetic interference (EMI) shielding windows, demonstrating excellent performance.

The study was published in iScience.

With the rise of the digital era, EMI significantly impacts electronic device performance and safety. Traditional shielding methods like metal mesh or conductive layers, though effective, compromise optical transparency and mechanical flexibility, limiting their use in transparent windows. Therefore, scientists are looking for new materials that can shield EMI while maintaining high transparency and flexibility.

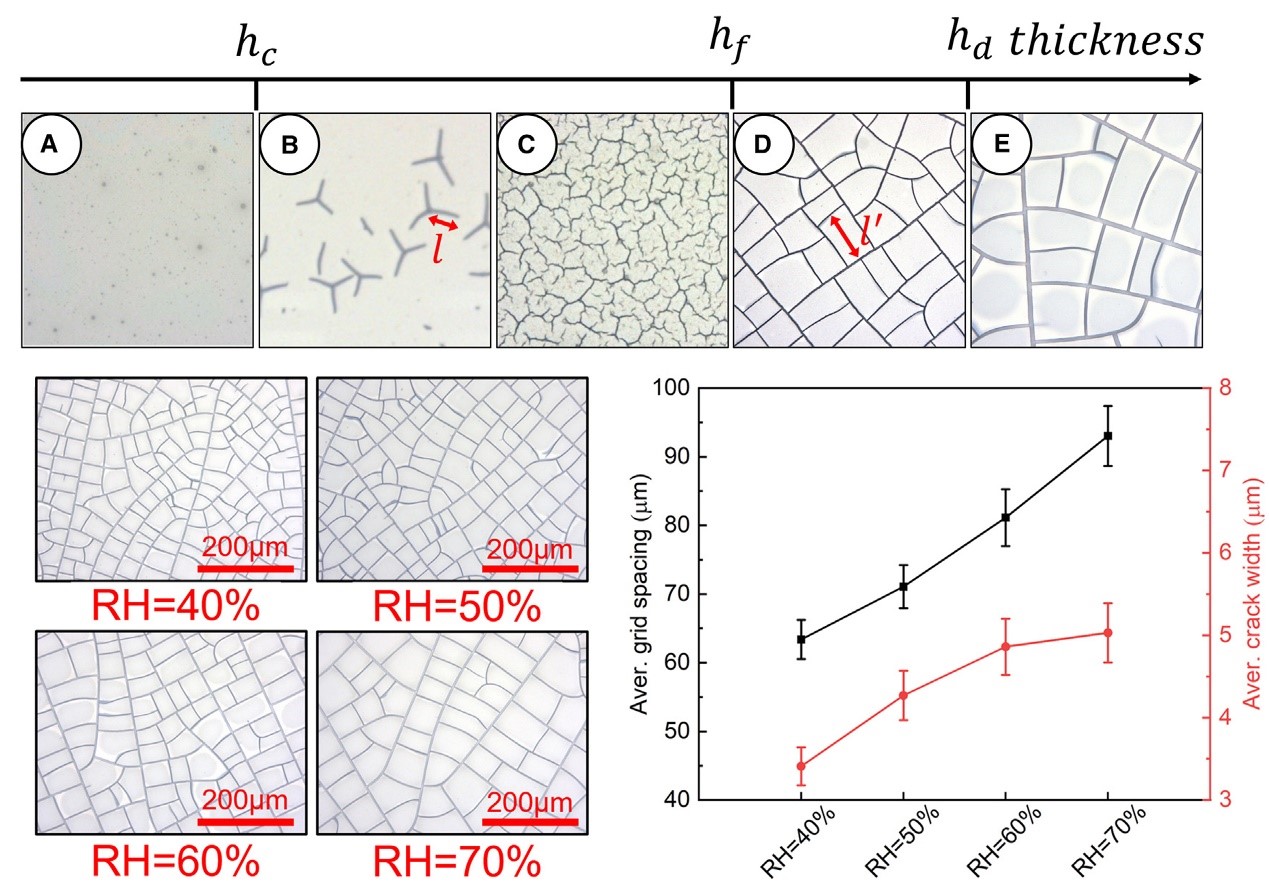

In this study, water-based acrylic solution served as the cracking material. By adjusting the hard monomer ratios, coating thickness, and drying methods, scientists achieved accurate control over the cracking patterns, producing templates with small gaps and thin lines. The metal grid film made with this template achieved outstanding transparent EMI shielding performance, with 82.7% optical light passing ability, 4.1 Ω/sq sheet resistance, and 33.6 dB shielding effectiveness across 1-18 GHz. Researchers also studied how cracks form, uncovering the link between mechanical stress and crack growth during drying.

“This research provides a low-cost, high-performance method for making transparent EMI shielding windows, suitable for aerospace, communication devices, and smart wearables.” said Prof. WANG Pengfei from XIOPM.

Fig. Analysis of crack pattern formation and statistical evaluation of grid spacing and crack widths.(Image by XIOPM)

Download: