Among the mid-IR soft glasses, germanate based heavy metal oxide (HMO) glasses exhibit great advantages over popularly investigated and used fluoride glasses due to their high rare-earth solubility, comparatively low phonon energy, superior infrared transparency, high damage threshold and strong mechanical strength, as well as low intrinsic absorption above 2 μm wavelength and feasibility of fiber fabrication, which makes germanate glasses attractive for laser operation on untested laser transitions in the 2-3 μm wavelength range and therefore potentially applied in high-energy mid-IR lasers.

How to reduce the mid-infrared attenuation loss due to absorption of hydroxyl (OH) groups and scattering of metallic species in HMO glasses, is still a fundamental problem to pave the way for their applications as ultra-low loss mid-IR HMO fiber optics for mid-IR high power lasering and mid-IR power delivery.

Recently, a research team led by Prof. WANG Pengfei from State Key Laboratory of Transient Optics and Photonics, Xi'an Institute of Optics and Precision Mechanics (XIOPM) of the Chinese Academy of Sciences has reported their work on the fabrication of low loss lead-germanate glass fiber through controllable methods and techniques. This work was done in collaboration with the team of Prof. Heike Ebendorff-Heidepriem from the University of Adelaide. The work was published back-to-back in the Journal of the American Ceramic Society (https://doi.org/10.1111/jace.17503, https://doi.org/10.1111/jace.17518).

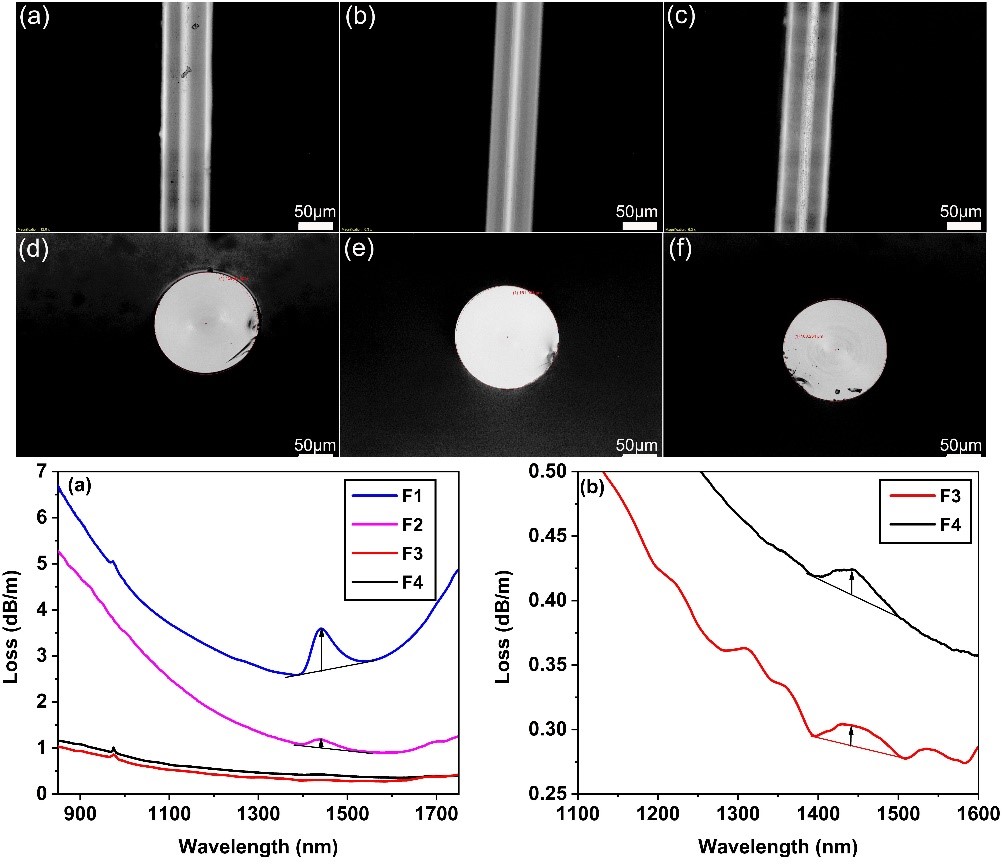

They explored the factors that determine dehydration efficiency and metallic Pb formation during the lead-germanate glass melting process. With further understanding of the co-effects of glass melting and heat treatment atmospheres on the formation of nano- and micron-scale metallic Pb species in lead-germanate glasses, low-loss lead-germanate glass fibers with no presence of reduced metallic Pb particles were successfully fabricated by optimizing dehydration agent, glass melting, preform extrusion and fiber drawing conditions. The optimized fabrication conditions reduced the unstructured fiber loss by almost one order to <0.3 dB/m at 1.55 μm compared to the lead-germanate glass fibers demonstrated to date.

This work guides for developing other low-loss mid-infrared glasses/fibers containing multivalent heavy metal ions such as Pb, Bi, Te, Sb, etc.

The lead-germanate Mid-IR HMO bare fibers fabricated by preform extrusion method and the fiber loss. (Image by XIOPM)

The lead-germanate Mid-IR HMO bare fibers fabricated by preform extrusion method and the fiber loss. (Image by XIOPM)

Download: