With the development of technology and the progress of urbanization, heavy metal pollution has become a huge problem facing society today. At the same time, heavy metal detection has become one of the most concerning issues of the public.

How to solve this problem? A research team led by Prof. Dr. KONG Depeng from Xi'an Institute of Optics and Precision Mechanics (XIOPM) of the Chinese Academy of Sciences (CAS) has given us a reliable answer.

They proposed a Ni2+ heavy metal sensor based on graphene oxide (GO) functionalized micro-tapered long-period fiber grating (MTLPG) where light-matter interaction is enhanced. The results were published in AppliedPhysics Express.

How did they do it?

In fact, the long-period fiber gratings (LPFGs) and two-dimensional (2D) materials have shown extensive applications in optical sensing, optical communications, light processing, chemical, and biochemical sensors.

Besides, graphene oxide (GO) as a very important derivate of graphene, it has similar properties to graphene. But the significant difference between GO and graphene is that hydrophilic oxygen functional groups such as epoxy, hydroxyl, and carboxyl are distributed on the basal planes and edges of GO. These oxygen-containing groups enable GO to be water-soluble and hydrophilic.

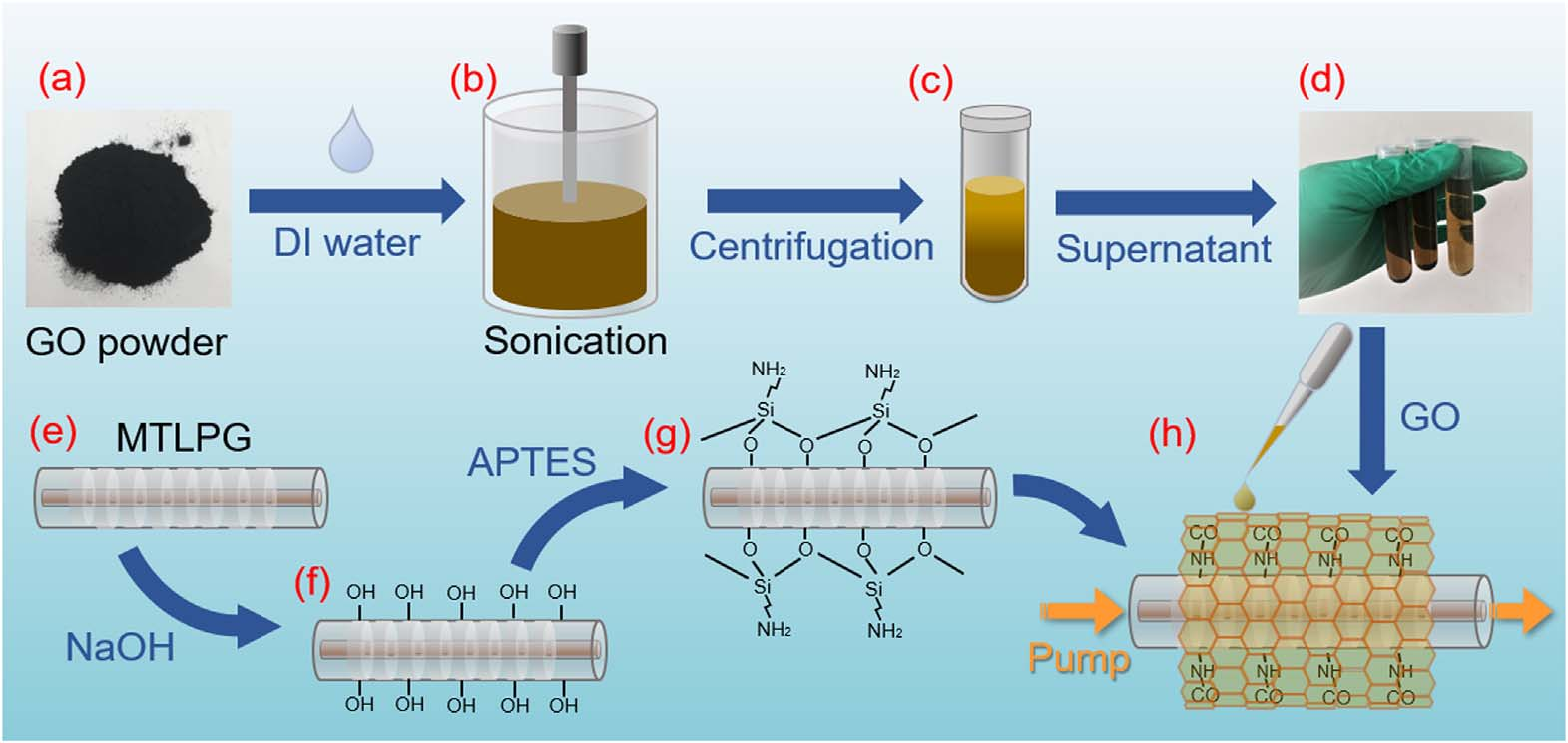

Schematic representation of GO nanosheet deposition process. (Image by XIOPM)

Schematic representation of GO nanosheet deposition process. (Image by XIOPM)

In this work, they deposited a GO supernate on the cylindrical surface of the MTLPG, which fabricated by a CO2 laser heating source, by a chemical bonding method associated with physical adsorption and assisted by the optical tweezer effect.

In terms of results, GO-fiber optic architecture features high sensitivity, real-time monitoring, stability, and reusability, and it provides a remarkable analytical platform for chemical and biochemical applications.

Download: