Nonequilibrium atmospheric-pressure plasmas have been extensively used in various practical applications such as material processing, thin film deposition, nanoscience, plasma medicine, biological sterilization, and chemical analysis, due to their prevailing advantage of avoiding the expensive vacuum system.

However, an individual plasma jet typically covers only a few mm2 and the spacing between each jet segment extends up to several or tens of millimeters and much larger than the plasma jet itself.

Thus, developing low-cost and low-power large-scale uniform plasma jet array with high activity is considerably challenging. How to break through low power discharge, large-gap discharge, large-scale discharge, parallel-multi-electrode discharge, and uniform discharge together proves to be the bottleneck of restricting generation of large and uniform plasmas.

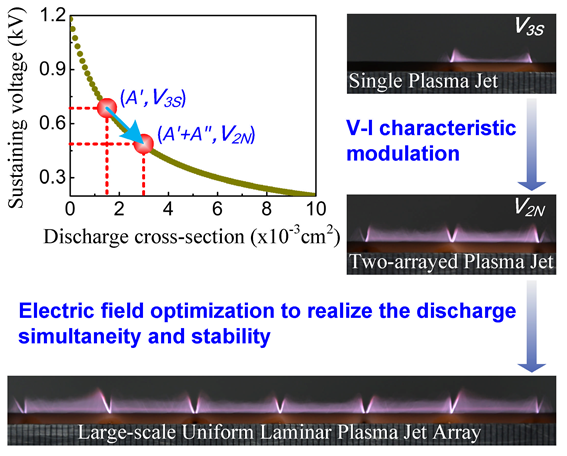

The technical roadmap of forming large-scale uniform laminar plasma jet array. ( Image by XIOPM )

The technical roadmap of forming large-scale uniform laminar plasma jet array. ( Image by XIOPM )

A research group led by Prof. Dr. Jie Tang from Xi'an Institute of Optics and Precision Mechanics (XIOPM) of the Chinese Academy of Sciences (CAS) demonstrated a new V–I characteristic modulation enhanced plasma approach in a non-self-sustained discharge, based on which a high-performance laminar plasma jet array (LPJA) with its width up to 90 mm is developed. It is the first time that this unique modulation method is used to reduce the discharge power and increase both the plasma jet length and chemical activity in an array. The result was published in Advanced Science(IF: 15.8 @2018) (https://doi.org/10.1002/advs.201902616).

In their experiment, the LPJA is designed based on the V–I characteristic modulation model in a non-selfsustained DC discharge. This device comprises two main parts: 1) a main discharge part integrated by six DC discharge cells and 2) a preionization part composed of DBD with two parallel copper strips (5 mm × 100 mm) set outside but close to the ceramic discharge chamber (1 mm thickness and 9.8 relative permittivity).

High pure argon (99.999%), controlled by a mass flowmeter, enters by the inlet port, flows through the discharge chamber, and gets weakly ionized in the DBD preionization region. The plasma is extended as a laminar brushshaped jet out of the discharge chamber through the outlet port due to the gas flow. As a result, a large array of laminar plasma jets is presented in front. The plasma generated in the device was imaged with a digital camera (Nikon D5200).

Under the support of discharge simultaneity and stability, a nested parallel circuit was designed to produce a LPJA with large scale. In addition, the alternating anode–cathode arrangement ensures a uniform plasma and a compact device. The independent switches provide an important flexibility for the local sample treatment and utmost energy saving.

Again by virtue of the nonequilibrium property and low-temperature feature, this LPJA can be efficiently used in processing various kinds of samples, irrespective of sample size and shape.

With these merits, this work not only breaks through the bottleneck of restricting the generation of large and uniform plasmas, but also provides a promising and productive approach for developing low-cost and highly efficient atmospheric plasma sources that are in urgent need for various plasma applications.

Download: