Based on the advantages of stress-free and non-liquid environment, ion beam polishing is the ideal processing technology for the Resin modified layer polishing of the carbon fiber mirror.

Since the glass transition temperature of the resin is low, the energy absorbed by the surface of the mirror during ion beam processing can cause localized high temperatures, which can lead to the risk of resin softening.

In this paper, the finite element analysis software was used to simulate the whole heat conduction process of Ion beam acting on the resin modified layer, and the optimum process parameters of the ion beam polishing were determined by a research team led by Dr. DING Jiaoteng from Xi'an Institute of Optics and Precision Mechanics (XIOPM) of the Chinese Academy of Sciences (CAS).

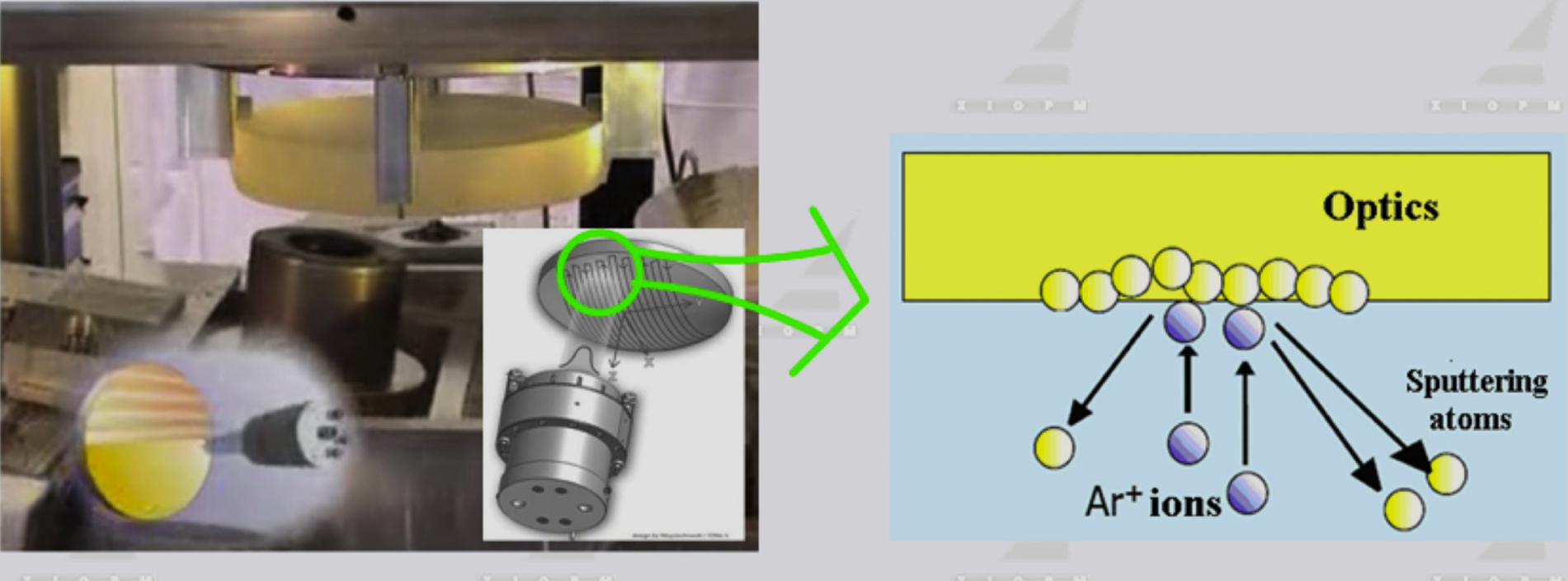

The principle of ion beam figuring. (Image by XIOPM)

At the same time, the resin layer surface polishing test was completed. The experimental results show that the surface polishing of the resin modified layer can be achieved by ion beam processing, and it has the convergence property and the correctness of the theoretical model is Verified.

In addition, according to the process instability phenomenon in the ion beam figuring of carbon fiber-based resin modified layer, analytical research on factors affecting the accuracy of ion beam processing were carried out.

The effects of various factors on the processing precision of carbon fiber resin layer were analyzed by combing and theoretical analysis, combined with experimental research to determine the amount of influence, and finally put forward corresponding solutions.

(Original research article “Optik - International Journal for Light and Electron Optics” (2020) https://doi.org/10.1016/j.ijleo.2019.163575)

Download: