In this study, a research team led by Prof. Dr. HE Zhengquan from Xi'an Institute of Optics and Precision Mechanics (XIOPM) of the Chinese Academy of Sciences (CAS) employed the CO2 laser heating source to experimentally fabricate tapered long-period fiber gratings (TLPFG) by periodically tapering a standard single-mode fiber (SMF) and fabricating the twisted CLPFGs by periodically rotating a standard SMF.

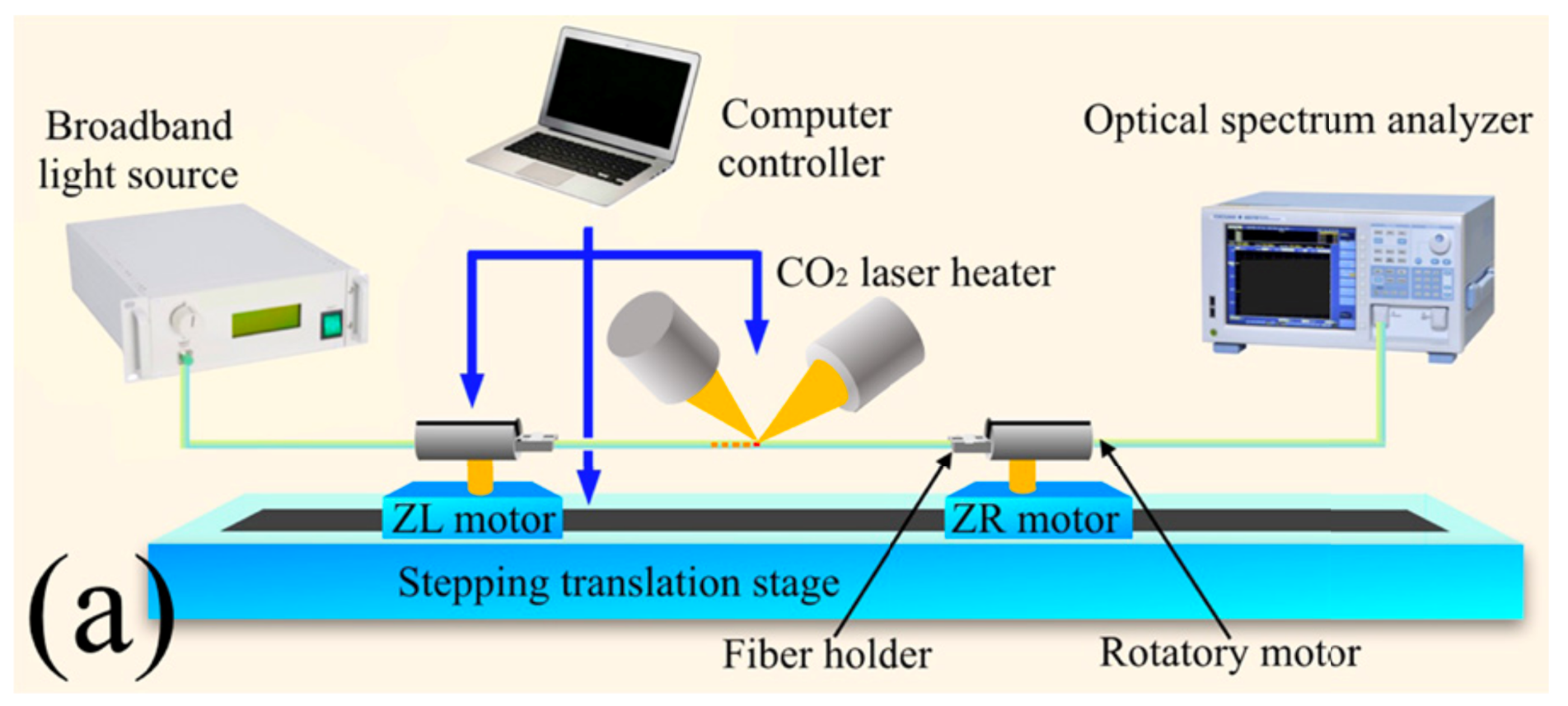

The experimental setup for fabricating the TLPFG and CLPFG by employing a double-beam CO2 laser heater. (Image by XIOPM)

The temperature sensing characteristics of the TLPFG and CLPFG between 30 °C and 60 °C were experimentally investigated, and the slopes of the wavelength shift corresponded to 0.115nm °C-1 and 0.04nm °C-1, respectively.

The graphene films were coated on gratings to fabricate graphene-coated TLPFG (GTLPFG) and graphene-coated CLPFG (GCLPFG). Given the thermal effects of graphene, the slopes of the resonance dip shift of the GTLPFG and GCLPFG between 30 °C and 60 °C increased to 0.196nm °C-1 and 0.113nm °C-1, respectively.

Additionally, the high temperature sensing properties of TLPFG and CLPFG between 100 °C and 1000 °C were investigated. The slopes of the higher-order resonance dips of the TLPFG and CLPFG corresponded to 0.119nm °C-1 and 0.09nm °C-1, respectively, during the heating process, and to 0.116 °C-1 and 0.09nm °C-1, respectively, during the cooling process.

In the low and high temperature zones, the TLPFG exhibited higher sensitivity when compared to that of the CLPFG, while the CLPFG exhibited higher sensing precision with linearity approaching 1.

Given the simple and unsophisticated fabrication process and the high quality and sensitivity of the fabricated gratings, the proposed sensors can play an important role in high-precision temperature-sensing applications.

(Original research article “Journal of Physics D: Applied Physics” (2020) https://doi.org/10.1088/1361-6463/ab5498)

Download: