Antireflective surfaces, with their great potential applications, have attracted tremendous attention and have been the subject of extensive research in recent years.

However, due to the significant optical impedance mismatch between a metal surface and free space, it is still a challenging issue to realize ultralow reflectance on a metal surface.

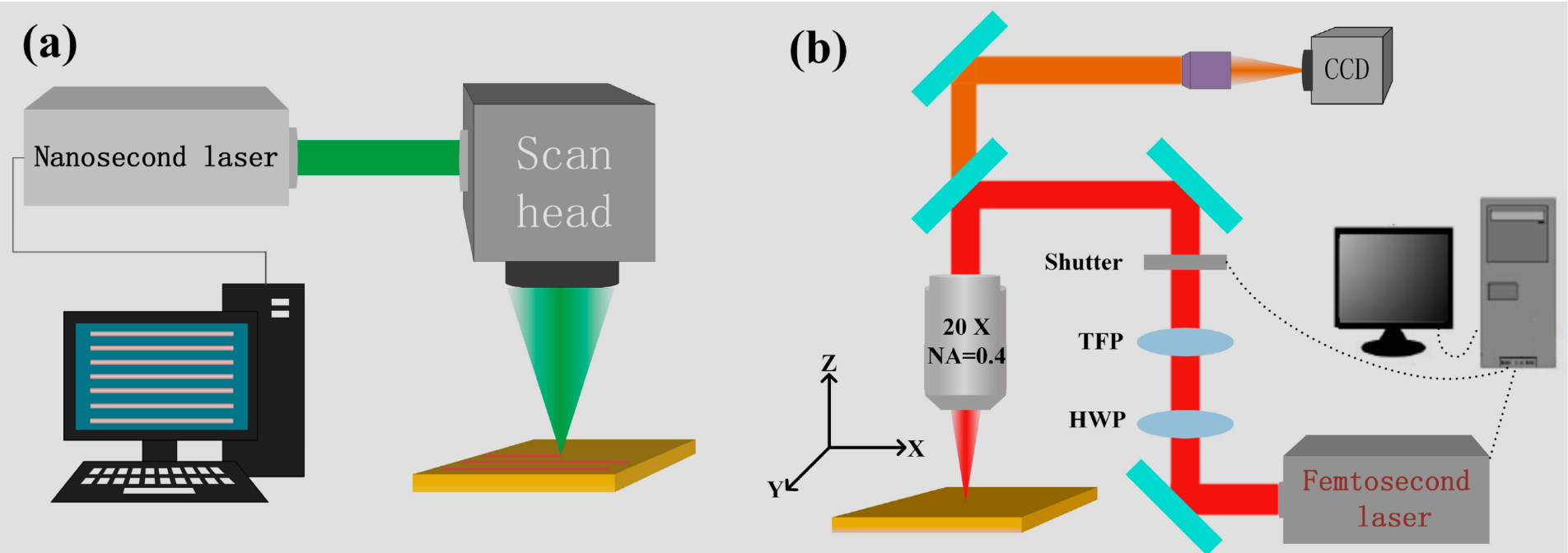

Schematic of the two-step nanosecond and femtosecond laser setup for fabrication of micro-nano hybrid structures on Ti-6Al-4V (TC4) surfaces. (Image by XIOPM)

Schematic of the two-step nanosecond and femtosecond laser setup for fabrication of micro-nano hybrid structures on Ti-6Al-4V (TC4) surfaces. (Image by XIOPM)

To address this issue, a research team from Xi'an Institute of Optics and Precision Mechanics (XIOPM) of the Chinese Academy of Sciences (CAS) propose a two-step strategy for constructing antireflective structures on a Ti-6Al-4V (TC4) surface using nanosecond and femtosecond pulsed lasers in combination. By controlling the parameters of the nanosecond laser, microgrooves are first scratched on the TC4 surface to reduce the interface reflection.

Then, the femtosecond laser is focused onto the sample surface with orthogonal scanning to induce deep air holes and nanoscale structures, which effectively enhances the broadband absorption.

The antireflection mechanism of the dual-scale structures is discussed regarding morphological characterization and hemispherical reflectance measurements. Finally, the modified sample surface covered with micro-nano hybrid structures is characterized by an average reflectance of 3.1% over the wavelengths ranging from 250 nm to 2250 nm.

(Original research article “Micro Machines” (2020) http://dx.doi.org/10.3390/mi11010020)

Download: