Humidity monitoring plays an important role in semiconductor industry, precision instrument manufacturing, medical industry and other fields. Optical fiber sensors, with advantages of small size, high temperature resistance, corrosion resistance, anti-electromagnetic interference, can also be applied to measure humidity. However, its sensitivity to the changes in relative humidity is still not high enough.

Many researchers have used a variety of polymers to cover the outer surface of the grating to increase its sensitivity. The polymer coating can absorb water and change its shape to cause strain on the fiber to affect the responding wavelength of the fiber Bragg grating.

Li Ziwan, researcher from Xi'an Institute of Optics and Precision Mechanics (XIOPM) of the Chinese Academy of Sciences, dressed another graphene jacket outside the polymer coating to the fiber sensor and achieved high sensitivity and stability. Results were published on Optical Fiber Technology

They put the FBG into the silane coupling agent and immersed for 40 min to get the polyimide coating. After heating the polyimide coating to get stabilized, they put the polyimide coated FBG into the groove and drip the mixed solution of graphene with absolute ethanol. After the alcohol gradually volatilizes, the graphene is deposited on the outer surface of the FBG. The unique two-dimensional structure of graphene makes it very sensitive to the surrounding environment.

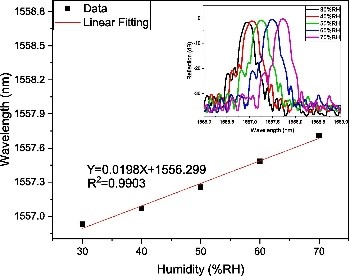

The unique two-dimensional structure of graphene makes it very sensitive to the surrounding environment. Experimental results show that its sensitivity is 1.80 times that of the sensor coated with only polyimide film. Within the humidity range of 30%–70%RH, its sensitivity is almost 25 times than that of the other lower sensitivity FBG humidity sensor. It is expected to have potential applications in humidity measurement area.

The reflectance spectrum drift of the sensor under different RH, and the linear relationship between wavelength drift and humidity. (Image by XIOPM)