ZnS is an important mid-infrared to far-infrared optical window which can significantly improve spectral transmission performance. However, the Fresnel reflection at the interface between the air and the high-strength substrate greatly limits the transmission of light, and deteriorates the signal intensity and thermal imaging quality.

To reduce Fresnel scattering and increase spectral transmittance, the concave antireflective subwavelength structures (ASS) was designed on ZnS. Nevertheless, conventional ASS processing method usually adapt femtosecond Gaussian beam, which results in a larger microstructure roughness and significant thermal effects on the surface of the material.

Now a research group led by Prof. Liu Hongjun from the Xi’an Institute of Optics and Precision Mechanics (XIOPM) has recently proposed a simple method to fabricate microhole array ASS by femtosecond Bessel beam, which further increased the depth of the microholes and suppressed the thermal effects effectively. The result was published on Molecules.

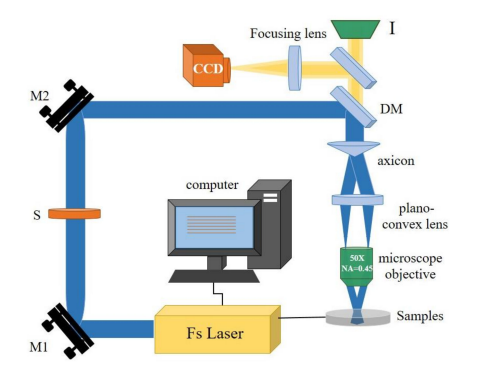

Experimental set-up of femtosecond laser Bessel beam processing system. (Image by XIOPM)

Experimental set-up of femtosecond laser Bessel beam processing system. (Image by XIOPM)

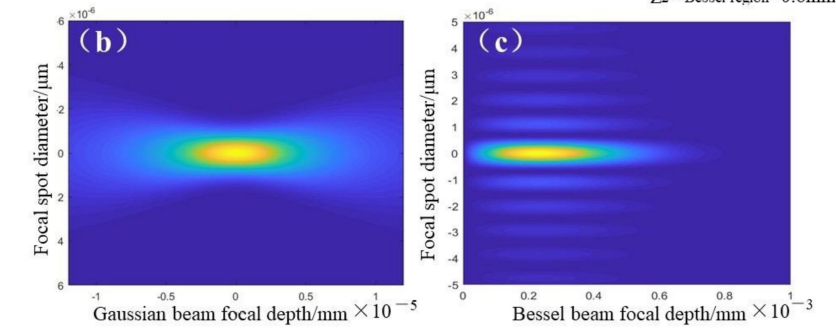

The researchers designed the optical system of the Bessel beam, and explored the difference of light intensity distribution between the Gaussian beam and Bessel beam. The results indicated that the Bessel beam further increases the depth of the microholes slightly and suppressed the thermal effects effectively.

Laser intensity distribution of Bessel Beam and Gaussian beam. (Image by XIOPM)

Laser intensity distribution of Bessel Beam and Gaussian beam. (Image by XIOPM)

Moreover, the Bessel beam reduces the energy density of the Gaussian beam along the optical axis by almost five hundred times to suppress surface splashes and resolidification, which can effectively reduce surface roughness. Low roughness can inhibit the scattering of infrared light on the inner wall of the microhole, which is beneficial to raise the infrared transmission light intensity of the microstructure.

This work was supported by the National Key R&D Program of China, Key Research and Development Program of Shaanxi Province.

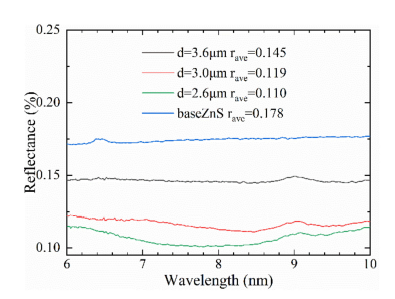

IR reflectance of the ZnS before and after ablating microhole array. (image by XIOPM)

IR reflectance of the ZnS before and after ablating microhole array. (image by XIOPM)