Light absorption surfaces on metal are of both fundamental interest and realistic values in various fields, such as aerospace, solar cells, artificial blackbodies and infrared imaging. To fabricate micro/nano structures on metal surfaces, various technologies have been proposed including chemical etching, mechanical grooving, reactive ion etching, and long-pulse laser processing.

Due to its simplicity, flexible machining of space, high processing accuracy, and environmental friendliness, ultrafast laser manufacturing technology is one of the relatively ideal technologies for fabricating light-trapping structure surfaces. However, fewer studies have been reported to simply and effectively achieve broadband effectiveness and ultralow average reflectivity performance on metal surfaces. Is there any effective strategy to obtain a metal surface with ultralow reflectivity?

A research team led by Prof. Dr. LIU Hongjun from Xi'an Institute of Optics and Precision Mechanics (XIOPM) of the Chinese Academy of Sciences (CAS) proposed an effective and simple method for fabricating the micro/nano hybrid structures on metal surfaces by adjusting femtosecond laser fluence, scanning interval, and polarization. The results were published in CHINESE OPTICS LETTERS.

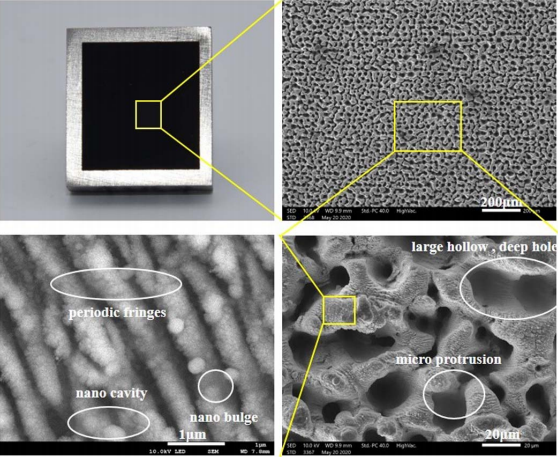

The blackened sample fabricated by the circularly polarized laser and its morphology. (Image by XIOPM)

The blackened sample fabricated by the circularly polarized laser and its morphology. (Image by XIOPM)

According to the researchers, A TC7 titanium alloy sample with a size of 25 mm × 25 mm × 10 mm was used in our experiments. The mechanically polished surface of the sample was cleaned in an ultrasonic cleaner with anhydrous ethanol and deionized water before laser treatment. For metal surface modification, an industrial fs laser with a high repetition rate (1 MHz) and the highest power (20 W) was employed.

In this research, the morphology of the samples fabricated by the fs laser changed greatly under different laser processing parameters was demonstrated. Moreover, an ultralow average reflectivity of 2% in the 250–2300 nm spectral band and minimum 1.5% reflectivity in UV band could be achieved.

According to the absorption principle of periodic nanostructures, the smaller the fringe period is, the better the resonance absorption of the short wave is. Since the hybrid nanostructure induced by circularly polarized light has a smaller fringe period, it has an excellent absorption of the short wave.

By employing the proposed method, large areas of the micro/nano hybrid structures with high consistency could be achieved for practical applications.