The unique features of ULE (an ultra-low thermal expansion glass), including low thermal expansion coefficient, good wear resistance and chemical inertness, are of great application prospects in space reflectors and large-aperture telescopes. However, conventional precision grinding restricts its efficiency and surface quality.

The appearance of ultrasonic vibration–assisted grinding (UVG) has been accepted as an effective method for processing hard and brittle materials with multiple benefits such as improving surface quality and increasing material removal rate. In general, the typical UVG modes are axial ultrasonic vibration–assisted peripheral grinding (AUPG) and end grinding (AUEG).

Due to the different relative motion between grinding wheel and ground surface during AUPG and AUEG, the effects on grinding mechanism and surface quality differ correspondingly. Is there any basis to choose an appropriate type of UVG?

A research team from Xi'an Institute of Optics and Precision Mechanics (XIOPM) of the Chinese Academy of Sciences (CAS) thoroughly investigated the differences between AUPG and AUEG in grinding process. The results were published in The International Journal of Advanced Manufacturing Technology.

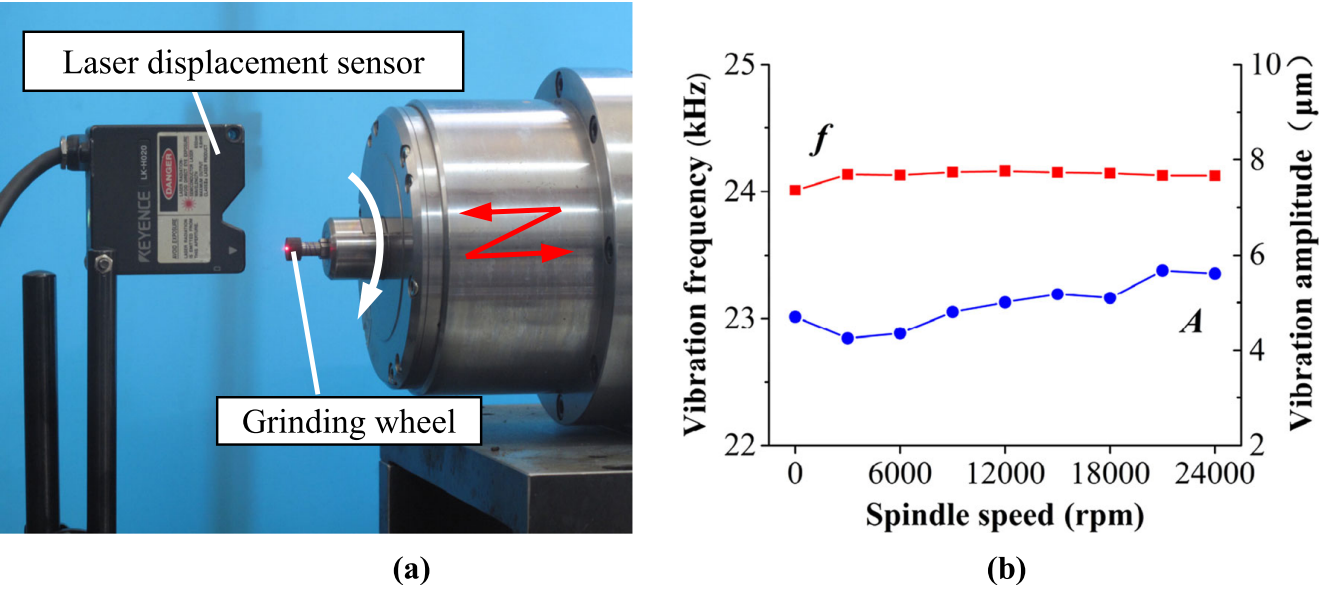

Schematic of the OVAs experimental setup and results.(Image by XIOPM)

The experiments were performed on a precision grinding machine equipped with an ultrasonic vibration air spindle system. Besides, the setup includes different kinds of grinding methods in order to explore the different effects of axial ultrasonic vibration parallel and vertical to the ground surface onto the grinding quality and efficiency.

According to the experimental comparison, the effect of axial ultrasonic vibration on grinding force and surface/subsurface quality during AUPG and AUEG are significantly different.

Moreover, much of this discrepancy is induced by the different comprehensive effects of axial ultrasonic vibration on workpiece contact, material properties, and material removal process.

The conclusion will be meaningful for researchers to choose the appropriate approach in applying axial ultrasonic vibration to grinding optical elements.