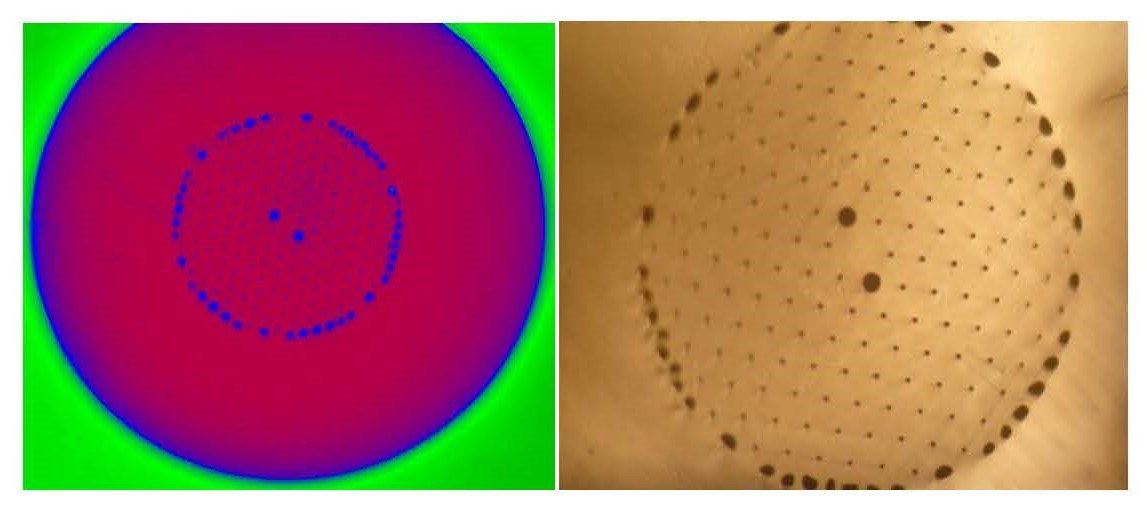

Light interacting with a band-gap (photonic) material would be totally reflected at a certain selected wavelength. The wavelength at which the stop-band would occur depends on the dimension and spacing of the crystals forming the material. The extension of the concept of photonic crystals from crystal lattices to fibers resulted in the design of photonic crystal fibers (PCFs) that could trap light inside, making it a perfect device for wave-guiding, in which the reproduction of the crystal lattice would be given by a periodic array of microscopic air holes that run along the entire fiber length. Especially, active PCFs with large mode area can up-scale the laser power up to tens of kW in one single fiber and passive LM-PCFs can be produced to deliver the high-power laser.

Mid-IR soft glasses (tellurite, fluoride, germinate glasses) are used to replace silica glass, giving the advantage of delivering a longer laser wavelength (>6μm) with much lower loss in Mid-IR can be achieved. The application of extrusion method will make the fabrication of hollow core fibers more feasible.