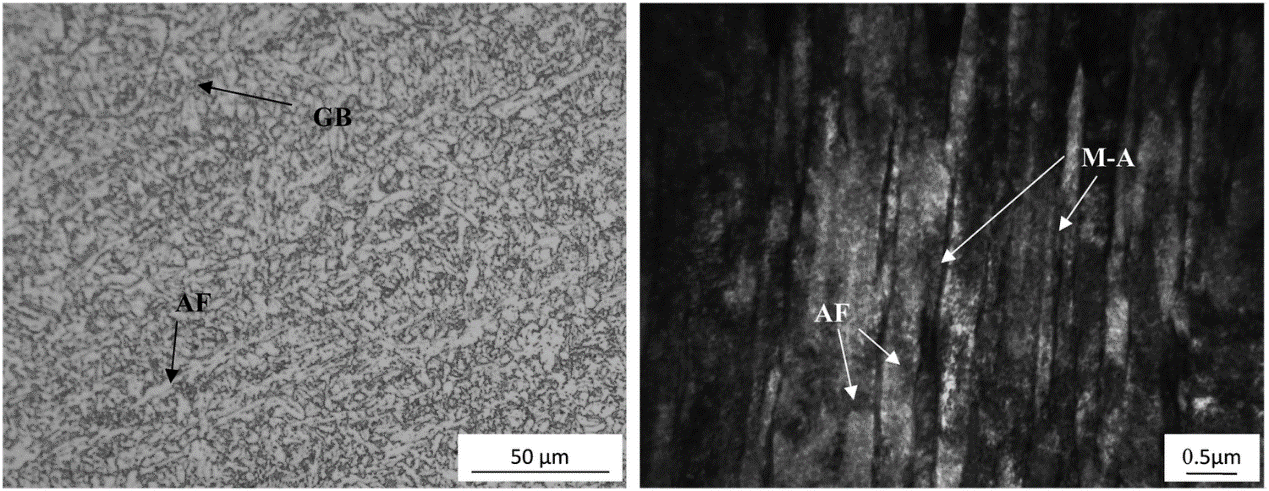

L8 (27) orthogonal test table is applied to design eight kinds of flux, and arranged with SiO2, ZrO2 and TiO2 as three factors. The microstructure, morphology and mechanical properties of low carbon bainitic steels are investigated by means of optical microscope, scanning electron microscope, transmission electron microscope, tensile testing machine and instrumented drop weight impact tester with oscilloscope. The results indicate that the optimum composition rate is as follows: 20% SiO2, 10% ZrO2, and 6% TiO2, and the interaction between ZrO2 and TiO2 is obvious. The microstructure of deposited metal of low carbon bainitic steel is mainly formed by acicular ferrite and granular bainite. The acicular ferrite is paralleled distribution, and plenty of fine sheet Martensitic–Austenitic constituents are dispersing, which can hinder crack propagation and improve strength and toughness. The impact energy is up to 109.7 J at ??20 °C, and the ratio of brittle fracture termination load to maximum impact load is 0.378, ensuring excellent crack arrest toughness.

OM image (a) and TEM image (b) of deposited metal. (Image by XIOPM)