3-5 μm mid-infrared (MIR) region is one of the most important atmospheric windows because it overlaps the molecular fingerprint area in which many kinds of pollutants and combustion gas products have intense absorptions especially the CO2 at around 4.2-4.4 μm. The unique spectral position and characteristic determine the widespread applications of 4 μm waveband lasers in chemical sensing, medical diagnostics, imaging, and etc. Presently, the ≥4 μm MIR lasers are mainly acquired through the carbon dioxide laser , the optical parametric oscillator, the quantum cascade laser and solid laser based on Fe2+: ZnSe crystal,a compact, reliable fiber laser operated beyond 4 μm waveband with low cost and high power is still scarce until now.

The restrictions for the birth of fiber laser beyond 4 μm are mainly account for the scarce of suitable optical materials. Chalcogenide glass (ChG) is promising optical glass with low phonon energy and optical loss to transmit laser beyond 4 μm and rare earth element doped ChG is promising active material for fiber laser beyond 4 μm.

A research group led by Professor Haitao Guo, from Xi'an Institute of Optics and Precision Mechanics (XIOPM) of the Chinese Academy of Sciences (CAS), synthesized Dy3+ doped Ga5Ge20Sb15S60 ChG with high rare-earth solubility and excellent fiberized performance, and developed a chemical purification method to further remove the impurities of O–H and S–H, both of which affect the performance of ChG glass in mid-infrared region. Furthermore, they successfully fabricated single-mode, double-cladding, Dy3+ doped, active fiber based on it for the first time in the world. The result has been published in JOURNAL OF THE AMERICAN CERAMIC SOCIETY.

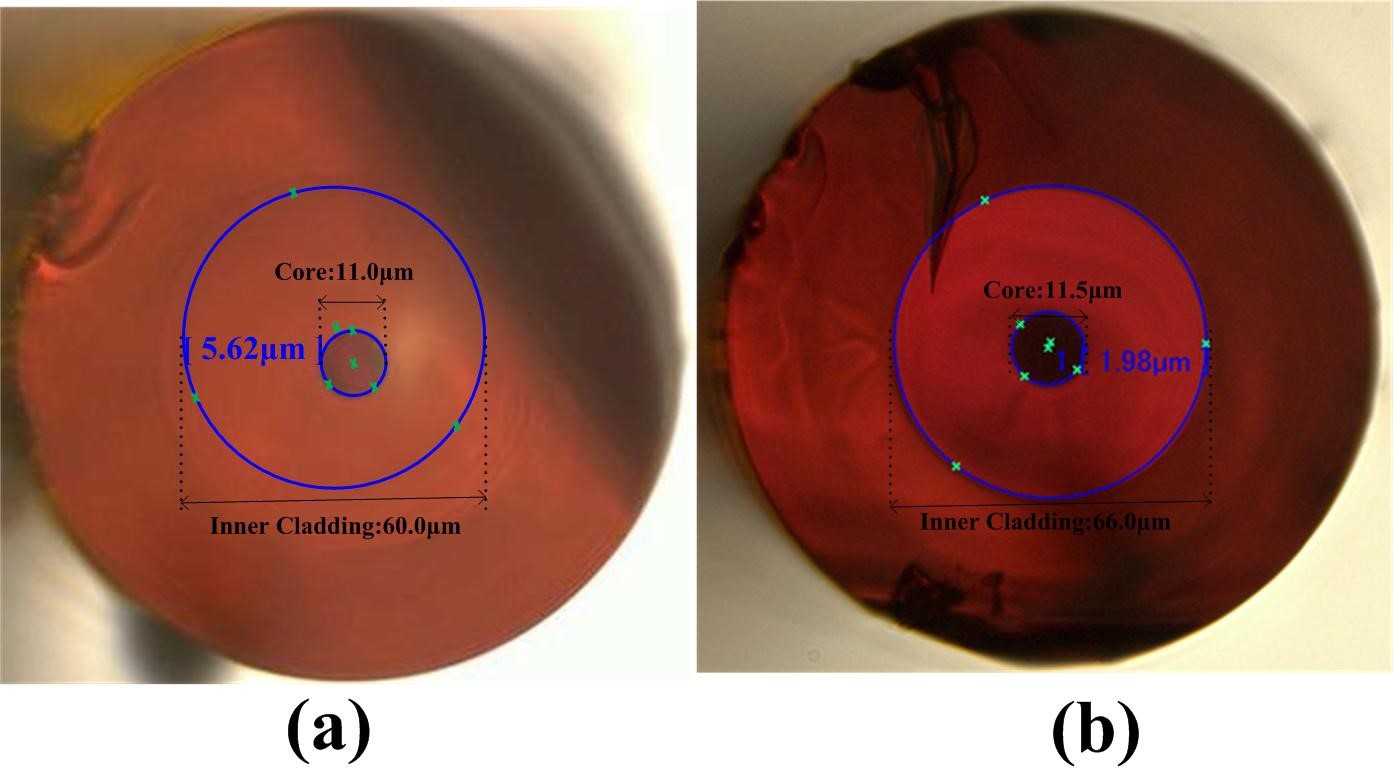

End-face view (transmitted light): (A) the fiber fabricated by multistage rod-in-tube method (B) the fiber fabricated by extrusion method (Image by XIOPM)

End-face view (transmitted light): (A) the fiber fabricated by multistage rod-in-tube method (B) the fiber fabricated by extrusion method (Image by XIOPM)

In their work, chlorine was adopted to purify the glass matrix and it successfully removed most harmful impurities in glass matrix to pave the way to draw fiber with high performance, where the impurities will cause more sever optical loss in certain wavelength bands. Then, fiber fabrication was completed by a multistage rod-in-tube fiber drawing process and extrusion method, in which the optimized active fibers with high-purity, low-loss, high doping concentration, and single-mode double-cladding structure were achieved.

Based on the fiber, the mid-IR window of chalcogenide glass toward 4 μm-band fiber laser development has been opened.