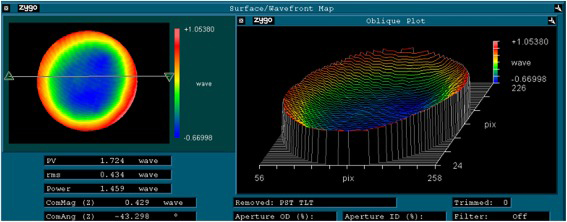

The aperture of space remote sensing camera is increasing, and the demand for lighter weight is getting higher and higher. With the advancement of active optics, the thickness of optical components has gradually grown to light and thin. It is extremely difficult to develop ultrathin mirrors using brittle materials such as traditional optical glass and silicon carbide. Due to advantages such as low density, high specific stiffness, low thermal expansion coefficient, toughness, and additive rapid manufacturing properties, carbon fiber reinforced plastic (CFRP) is one of potential applications for large-diameter ultra-thin mirrors. However, the carbon fiber composite material is a two-phase material that cannot be used as optical surface and must be surface-modified. In this paper, Liang Xu’s research team carried out the surface modification of CFRP substrate by chemical nickel plating and nickel electroplating. The modified nickel layer covers all surfaces of CFRP substrate, and nickel layers satisfying the thickness, bonding force, and internal stress requirements. A Phi 100 mm aperture ultra-thin carbon fiber mirror developed, after optical fabricating, its surface accuracy RMS is better than lambda/15. Thermal deformation analysis and test show that the thermal deformation of ultra-thin carbon fiber mirrors is mainly manifested by the change of radius of curvature, which is caused by the thickness error of the nickel layer on the front and rear faces. In addition, although thermal deformation caused by the lamination angle error of CFRP substrate is relatively small in value, it should still be given enough attention, because the astigmatic error produced is hard to eliminate.

(Original research article "Optik Vol. 176, pp. 85-92 (2019) https://linkinghub.elsevier.com/retrieve/pii/S0030402618313895")